Description

Concertina Razor Wire Coiling Machine: What It Is and Why You Need It

A Concertina Razor Wire Coiling Machine is a specialized device used to shape and coil razor wire into concertina form. This equipment is crucial in the production of security barriers, especially for fencing in high-risk zones. The machine automates the coiling process, reducing manual labor and increasing production consistency.

By using a Coling Machine designed for concertina wire, manufacturers can increase productivity while minimizing waste and worker fatigue.

What Is a Concertina Razor Wire Coiling Machine

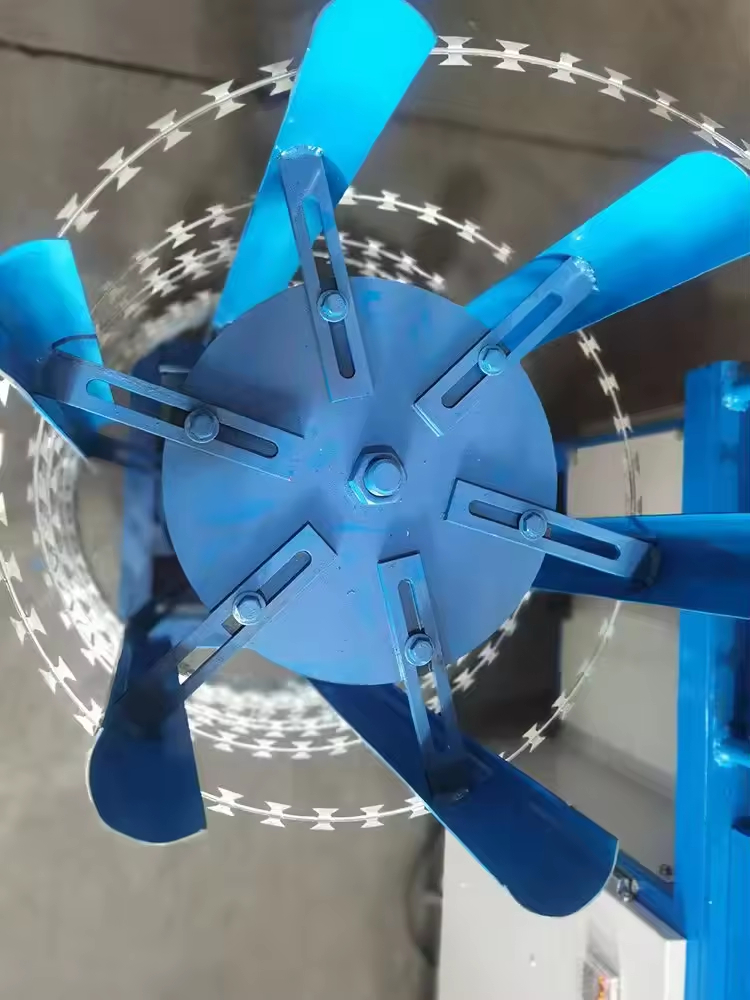

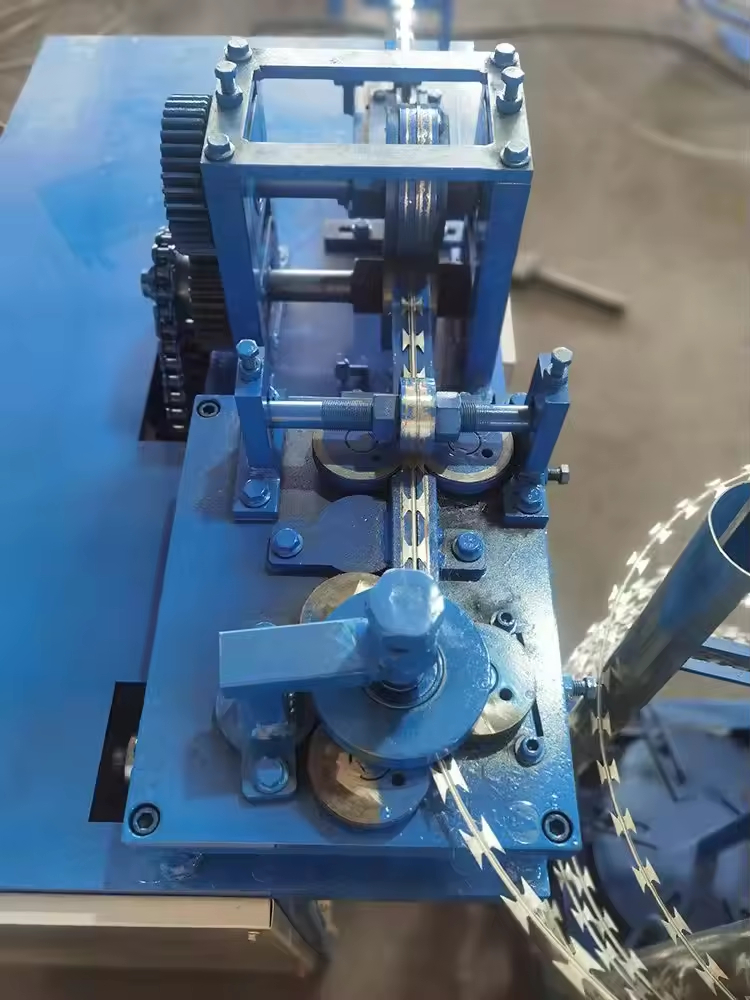

A Coling Machine for razor wire is an industrial tool that coils razor wire into tight, uniform spirals. It works by feeding the wire through a set of rollers and arms that form it into concentric loops. These loops are then tied or clipped into the finished concertina form.

Unlike basic wire forming tools, these machines are built to handle the sharp edges of razor wire safely and efficiently.

Core Components:

Precision motor and gear system

Coil former assembly

Adjustable pitch controls

Tension control unit

Safety shields and emergency stop systems

Use Cases Across Industries

Military and Border Control

Used to quickly deploy security fences at borders and conflict zones.

Correctional Facilities

Keeps perimeters of prisons secure with uniform, high-tension coils.

Industrial Zone Security

Protects warehouses, plants, and restricted sites efficiently.

Construction Site Protection

Allows fast production of temporary fencing material on demand.

Key Features to Look For in a Razor Wire Coling Machine

When choosing the right machine, focus on:

-

Coiling Speed (m/min): Higher speed means more output.

-

Wire Compatibility: Should support BTO-10, BTO-22, CBT-65, and more.

-

Automation Level: Choose from manual, semi, or full-auto.

-

Power Consumption: Go for efficient systems with low energy use.

-

After-Sales Support: Important for installation, maintenance, and training.

How to Choose the Right Concertina Razor Wire Coiling Machine

Here’s a quick guide to help you pick the ideal model:

| Criteria | What to Check |

|---|---|

| Coil Type | Flat, spiral, or cross-type |

| Wire Type | Galvanized, stainless steel, etc. |

| Production Volume | Daily or weekly output targets |

| Power Supply | Match local voltage and power specs |

| Space Available | Make sure you have room to operate |

Always test the machine or request a video demo. Confirm it includes manuals and spare parts.

Common Issues and Solutions with Razor Wire Coiling Machines

Wire Slippage

Use machines with tension control to prevent slippage.

Coil Misalignment

Check and reset the pitch calibration.

Blade Jamming

Clean out buildup regularly and inspect rollers.

Inconsistent Coils

Adjust feed speed and check wire tension.

Tips for Maintenance and Longevity

-

Clean the machine daily to prevent buildup.

-

Schedule monthly inspections of belts and motors.

-

Apply lubricant to all moving parts on a regular basis.

-

Train workers before operation.

Routine care helps you avoid costly downtime and extends machine life.