Description

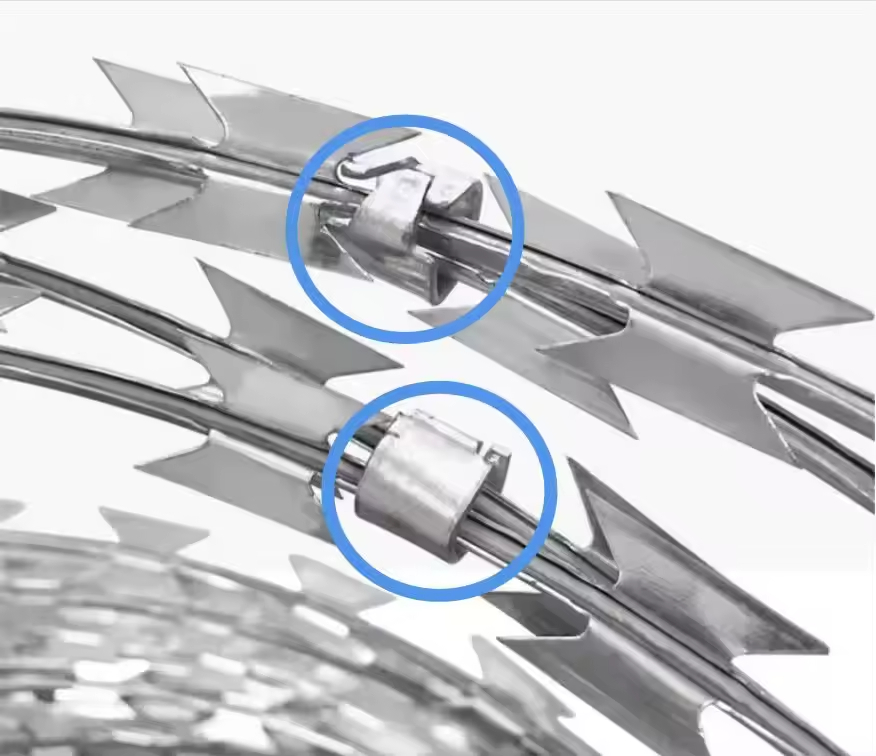

Galvanized clinch clips are essential hardware for securing razor wire. These clips hold sharp wire coils in place, ensuring tightness, stability, and safety in high-security fencing. In this article, we’ll explore their uses, benefits, how to choose the right product, and what makes our clinch clips the right choice.

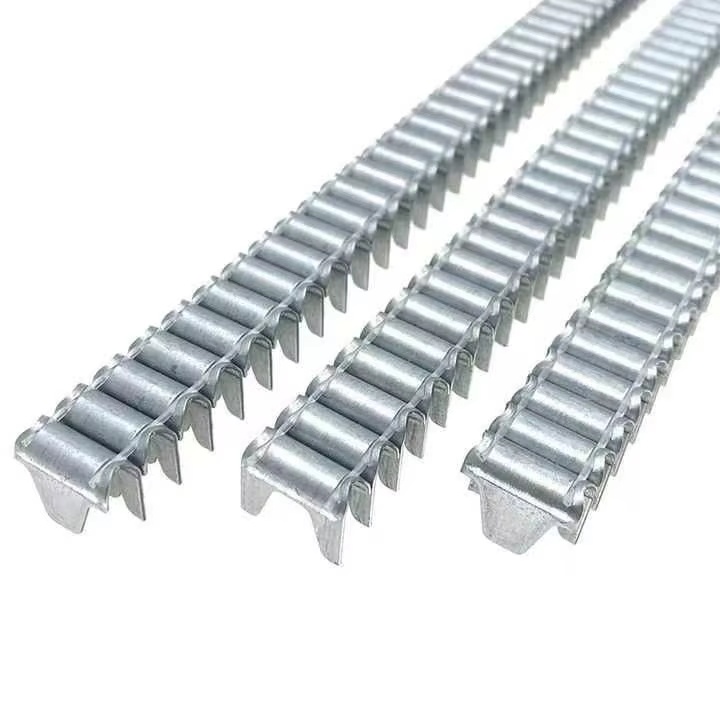

What Are Galvanized Clinch Clips?

Galvanized clinch clips are small steel fasteners treated with a zinc coating to resist rust. They’re specifically used to bind the overlapping points of razor wire coils. These clips keep the wire taut and aligned, improving both security and durability.

Benefits of Using Galvanized Clinch Clips

Using galvanized clinch clips for razor wire brings several critical advantages:

-

Corrosion resistance: Zinc coating protects clips from rain, moisture, and extreme temperatures.

-

Strong grip: The clips offer tight closure, preventing coil slippage or sagging.

-

Time efficiency: Faster and easier than tying wire manually.

-

Reliable safety: Maintains coil spacing, reducing the risk of razor wire unraveling.

-

Lower maintenance: Long-lasting, even in outdoor and remote installations.

Compared to standard steel fasteners, galvanized clinch clips have a longer working life and reduce long-term fence repair needs.

How to Choose the Right Clinch Clips for Razor Wire

Selecting the correct galvanized clinch clips depends on your installation environment and security goals. Consider the following factors:

1. Clip Gauge and Size

-

Match clip gauge to wire diameter.

-

Common sizes include 1.3mm to 2.2mm thick, depending on coil density.

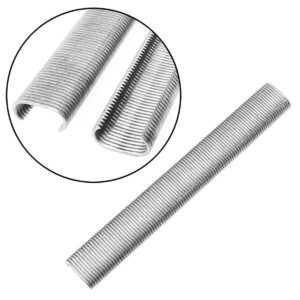

2. Clip Shape and Type

-

C-shape: Most common for razor wire and easy to apply with pliers or air tools.

-

D-shape: Offers tighter locking but used less often in razor wire applications.

3. Tool Compatibility

-

Always confirm the clip matches your pneumatic clinch gun or manual pliers.

-

Misfitting clips can cause poor crimping or jamming.

4. Application Volume

-

For small jobs, manual tools are fine.

-

For long stretches or frequent installation, use pneumatic tools to save time and effort.

5. Environmental Exposure

-

Galvanized clips are best for humid, coastal, or rainy regions.

-

For extreme conditions, opt for hot-dipped galvanization instead of electroplated.

Common Problems and How to Solve Them

Problem: Clips corrode too fast.

Solution: Choose heavy zinc-coated galvanized clinch clips, especially for high-moisture environments.

Problem: Razor wire coils sag or open.

Solution: Use the right gauge and spacing when installing clips. Place one clip every 12–15 inches along the overlap.

Problem: Tool jams during application.

Solution: Confirm clip dimensions match the tool’s specifications and keep tools clean.

Why Choose Us for Galvanized Clinch Clips?

We manufacture and supply galvanized clinch clips built specifically for razor wire and fencing applications. Here’s why businesses worldwide trust our products:

-

Consistent quality: Every clip undergoes strict batch testing.

-

Wide compatibility: Fits most manual and pneumatic clinching tools.

-

Available in bulk: Ideal for large-scale fencing contractors.

-

Quick delivery: We maintain ready stock for faster order fulfillment.

-

Expert guidance: Our team helps you choose the right clips for any project.

We also provide packaging and labeling options to support wholesale, retail, or military use.

Installation Tips for Razor Wire Clinch Clips

-

Wear gloves and eye protection: Razor wire is sharp and dangerous.

-

Space clips evenly: Use a clip every 30–40 cm for even tension.

-

Avoid over-crimping: Too much pressure can deform the clip or wire.

-

Test before finalizing: Check your first few crimps for tightness and durability.

Correct application improves both safety and performance of your security fencing.

Maintenance and Best Practices

-

Regularly inspect fences for signs of rust or loose clips.

-

Replace damaged or missing clips immediately.

-

Store unused clips in dry, sealed containers to prevent early corrosion.

A little maintenance can extend your fence’s effectiveness by years.

Frequently Asked Questions

Q: Can clinch clips be used with barbed wire too?

A: Yes, but they are primarily made for razor wire due to their tight fit and corrosion resistance.

Q: How many clips per roll of razor wire?

A: Typically, 3–5 clips per coil overlap. A 500-meter fence may use over 1,000 clips depending on spacing.

Q: Are these clips reusable?

A: No. Once crimped, they are permanent and should not be removed or reused.

Q: Do you offer hot-dipped galvanized clips?

A: Yes. We supply both electro-galvanized and hot-dip options depending on environmental needs.

Galvanized clinch clips are small, but they play a huge role in keeping razor wire effective and secure. By choosing the right type and applying them properly, you increase safety and reduce maintenance. Whether you’re building fences for security, defense, or perimeter control, investing in quality clips makes all the difference.

Work with us to get high-performance galvanized clinch clips backed by service, stock, and support.