Description

What Is the Razor Wire BTO Series Clips Making Machine?

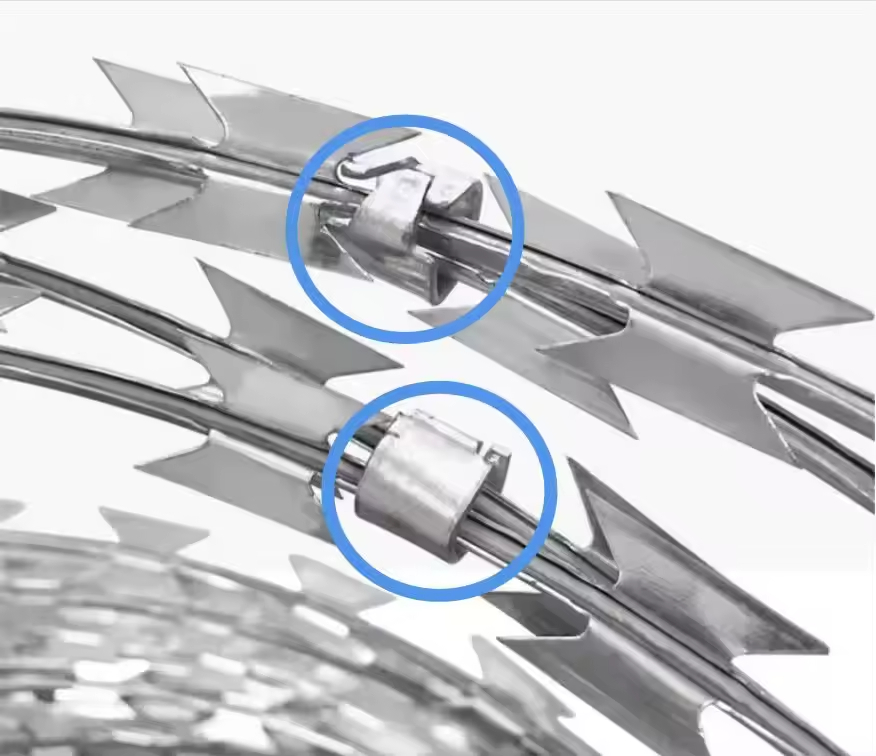

The Razor Wire BTO-16 BTO-22 BTO-30 Series Clips Making Machine is an industrial tool that produces clips used to join razor wire coils. These clips are essential for forming concertina wire or reinforced fencing. Each machine is customized for different clip sizes like BTO-16, BTO-22, and BTO-30, offering flexible support for common razor wire profiles.

This clips making machine transforms raw wire into precise, durable clips—ideal for high-strength wire assembly.

Key Benefits of Using a Razor Wire Clips Making Machine

-

Accurate Clip Formation

Each clip is formed to strict tolerances, fitting BTO-16, BTO-22, or BTO-30 profiles without error. -

High-Speed Production

This machine can produce thousands of clips per hour, supporting continuous assembly line work. -

Minimal Material Waste

It processes wire with optimized cutting and shaping systems, reducing scrap rates. -

Stable Operation

Its simple mechanical design minimizes breakdowns and boosts long-term output stability. -

Flexible Output Options

Easily switch tooling or settings to produce different clip sizes from one base machine.

Use Cases in Industrial and Security Operations

Razor Wire Manufacturers

This machine forms clips for use with flat and concertina coils in razor wire production lines.

Security Contractors

Field teams use the clips made by this machine to install barriers at military bases, borders, or high-risk zones.

Government Prison Construction Projects

Facilities rely on razor wire clips to strengthen prison fencing and eliminate gaps.

Critical Infrastructure Protection

Power stations, airports, and chemical plants use reinforced razor wire held together with these clips.

Disaster & Riot Control Installations

Temporary fences built for crowd control or emergencies depend on fast clip availability.

Technical Features of the BTO Razor Wire Clips Making Machine

-

Supported Clip Types: BTO-16, BTO-22, BTO-30

-

Wire Diameter Range: Usually 1.8–2.2 mm (can vary)

-

Feeding System: Automatic wire feed with straightening

-

Cutting Mechanism: Precision blade assembly with timing control

-

Control Panel: Simple button interface with speed settings

-

Frame Build: Steel body with anti-vibration feet

Its compact structure and ease of operation make it suitable for both large and medium-sized factories.

How to Choose the Right Clips Making Machine for Razor Wire

Here’s a checklist to help select the best clip making machine for your application:

| Requirement | Checkpoint |

|---|---|

| Clip Type Needed | BTO-16 / BTO-22 / BTO-30 |

| Daily Output Target | Can the machine meet your production rate? |

| Wire Source | Is the wire you use compatible? |

| Factory Voltage | Does it match your local electrical setup? |

| Tooling Availability | Can parts be swapped easily when needed? |

Making the right decision early on will reduce future maintenance and operational issues.

Solving Common Clip Production Challenges

-

Clips Too Loose: Adjust pressure setting and wire alignment.

-

Irregular Size: Calibrate cutting and shaping units regularly.

-

Wire Jam: Clean feed rollers and avoid bent wire.

-

Burrs on Clip Edges: Sharpen or replace cutter blades.

Regular inspection ensures consistent clip quality and safe machine performance.

Maintenance Tips for Long-Term Machine Health

-

Perform daily cleaning and remove leftover wire debris.

-

Lubricate moving parts twice per week.

-

Monitor cutter wear and replace dull blades.

-

Check wire straighteners weekly to avoid jams.

-

Store in a dry, dust-free environment when idle.

These small habits lead to longer life and fewer repair costs.